The

CLK32K is Kleemanns designation for the CLK320 when supercharged. The

Kleemann supercharger is the full kit, which includes intercooler and ECU flash.

This particular setup also uses a custom made 70mm pulley, which increases the

boost from .5 bar to .6 bar. Also included with this particular conversion

is a electric water pump with metal impellers (stock has plastic impellers).

The result is a increase from the stock hp of 215 to roughly 345 hp.

Coupled with the 3.27:1 rear differential (from a C230) this car is extremely

fast.

The

CLK32K is Kleemanns designation for the CLK320 when supercharged. The

Kleemann supercharger is the full kit, which includes intercooler and ECU flash.

This particular setup also uses a custom made 70mm pulley, which increases the

boost from .5 bar to .6 bar. Also included with this particular conversion

is a electric water pump with metal impellers (stock has plastic impellers).

The result is a increase from the stock hp of 215 to roughly 345 hp.

Coupled with the 3.27:1 rear differential (from a C230) this car is extremely

fast.

Here we see the drive belt removed as we prepare to remove the 76mm stock SC

pulley and install the smaller, 70mm custom made pulley

This

is a specialty tool used to remove pulley's. Thanks to Alex at CarbCon in

Kirkland for doing the installation for me

This

is a specialty tool used to remove pulley's. Thanks to Alex at CarbCon in

Kirkland for doing the installation for me

You

can see the stock 76mm pulley vs. the 70mm custom made pulley

You

can see the stock 76mm pulley vs. the 70mm custom made pulley

Another

picture of the 70mm pulley before installation

Another

picture of the 70mm pulley before installation

Another

view of the Kleemann supercharger. The stock engine cover no longer fits,

so the engine does look a bit bare, but with a few modifications, I should be

able to at least get part of the engine cover to fit.

Another

view of the Kleemann supercharger. The stock engine cover no longer fits,

so the engine does look a bit bare, but with a few modifications, I should be

able to at least get part of the engine cover to fit.

The

stock engine covers don't fit over the Kleemann supercharger, so my original was

cut down to fit. This didn't look very good, so I decided to purchase a

new OE cover and modify it to fit. I had a slight mishap with my digital

camera, so I don't have any progression pictures, just the finished product.

It took me four days of cutting/sanding to get the cover to fit over the SC and

all the associated piping.

The

stock engine covers don't fit over the Kleemann supercharger, so my original was

cut down to fit. This didn't look very good, so I decided to purchase a

new OE cover and modify it to fit. I had a slight mishap with my digital

camera, so I don't have any progression pictures, just the finished product.

It took me four days of cutting/sanding to get the cover to fit over the SC and

all the associated piping.

The

majority of work was concentrated on cutting away the center section of the

cover, of course, the underside needed trimming and as a result of this, not all

of the original mounting clips are still intact. Painting involved sanding

with 400 grit, application of a adhesion promoter and then finally body matched

paint. The star was removable and painted separately using a chrome paint.

The letters were hand painted using the same chrome paint. The hand

lettering took an entire day, but the end results were worth the effort.

The

majority of work was concentrated on cutting away the center section of the

cover, of course, the underside needed trimming and as a result of this, not all

of the original mounting clips are still intact. Painting involved sanding

with 400 grit, application of a adhesion promoter and then finally body matched

paint. The star was removable and painted separately using a chrome paint.

The letters were hand painted using the same chrome paint. The hand

lettering took an entire day, but the end results were worth the effort.

Like

I mentioned in my previous caption, not all the mounting clips were left intact,

you can see that I had to add a grommet and use a wire tie to hold the left

passenger side front corner down. This is somewhat inconvenient, as now I

need to keep wire tires and a pair of cutters in my car. (in the event I need to

remove the cover)

Like

I mentioned in my previous caption, not all the mounting clips were left intact,

you can see that I had to add a grommet and use a wire tie to hold the left

passenger side front corner down. This is somewhat inconvenient, as now I

need to keep wire tires and a pair of cutters in my car. (in the event I need to

remove the cover)

You

can also see that now the MAF sits correctly, as the other part of this upgrade

was replacing the C36 airbox cover with a OE cover (mentioned in the next

section)

You

can also see that now the MAF sits correctly, as the other part of this upgrade

was replacing the C36 airbox cover with a OE cover (mentioned in the next

section)

C36 Airbox Installation

The

stock airbox for the CLK320 is designed to flow enough air for a 3.2l motor

putting out 215 hp. Since this car now puts out 345 hp, the stock

airbox did not flow enough air. Aftermarket air intakes can provide the

needed air flow, but they also have a tendency to draw hot air from the

engine bay. After numerous tests, the aftermarket air intake was scrapped

in lieu of a MB solution. The C36 airbox is a modified C280 box, which

includes a scoop (shown in this picture on the bottom of the main intake).

This scoop draws cold air from the lower bumper area in conjunction to the air

intake next to the radiator. This was the modification AMG came up with to

feed a 3.6l motor (versus the 2.8l of the C280).

The

stock airbox for the CLK320 is designed to flow enough air for a 3.2l motor

putting out 215 hp. Since this car now puts out 345 hp, the stock

airbox did not flow enough air. Aftermarket air intakes can provide the

needed air flow, but they also have a tendency to draw hot air from the

engine bay. After numerous tests, the aftermarket air intake was scrapped

in lieu of a MB solution. The C36 airbox is a modified C280 box, which

includes a scoop (shown in this picture on the bottom of the main intake).

This scoop draws cold air from the lower bumper area in conjunction to the air

intake next to the radiator. This was the modification AMG came up with to

feed a 3.6l motor (versus the 2.8l of the C280).

This

is the airbox with the top scoop installed and the radiator piece still

installed. The radiator filler piece is obviously from a W202 and does not

fit the W208, so I will be using the stock CLK320 radiator filler piece.

The C36 is based off the W202 platform, same with the CLK320.

This

is the airbox with the top scoop installed and the radiator piece still

installed. The radiator filler piece is obviously from a W202 and does not

fit the W208, so I will be using the stock CLK320 radiator filler piece.

The C36 is based off the W202 platform, same with the CLK320.

This

is the C36 stock filter, not too different from the C280 filter, except that it

is notched so it does not restrict air flow from the lower scoop.

This

is the C36 stock filter, not too different from the C280 filter, except that it

is notched so it does not restrict air flow from the lower scoop.

To

further increase air flow, I chose to use a K&N filter. These filters by

themselves don't provide much of a HP increase, but every bit helps!

To

further increase air flow, I chose to use a K&N filter. These filters by

themselves don't provide much of a HP increase, but every bit helps!

The

K&N comes pre-oiled and ready to install. I have used this filters for

many years without any negative effects.

The

K&N comes pre-oiled and ready to install. I have used this filters for

many years without any negative effects.

Before

I installed the K&N, a good cleaning to the interior of the airbox was

necessary.

Before

I installed the K&N, a good cleaning to the interior of the airbox was

necessary.

Here

is the filter installed and ready for the top to be put back on.

Here

is the filter installed and ready for the top to be put back on.

This

is the engine bay minus the stock airbox. There are additional water lines

that need to be carefully routed around the new box. I also took replaced

the rubber mounts for the airbox while I was at it.

This

is the engine bay minus the stock airbox. There are additional water lines

that need to be carefully routed around the new box. I also took replaced

the rubber mounts for the airbox while I was at it.

Because

the C36 used a older MAF design, I had to modify the inside of the airbox tubing

to accept the newer CLK MAF. The clip points are also skewed, which

results in the MAF being being rotated about 30 degrees upwards. I used a

small piece of rubber intake tubing to make a ring to seal the MAF to the airbox.

Because

the C36 used a older MAF design, I had to modify the inside of the airbox tubing

to accept the newer CLK MAF. The clip points are also skewed, which

results in the MAF being being rotated about 30 degrees upwards. I used a

small piece of rubber intake tubing to make a ring to seal the MAF to the airbox.

Test

fitting of the airbox and MAF. I needed to re-route some of the coolant

hoses, but overall the C36 airbox fits very well.

Test

fitting of the airbox and MAF. I needed to re-route some of the coolant

hoses, but overall the C36 airbox fits very well.

The

MAF wiring needed to be taken apart and separated a bit from the main harness

and re-routed over some water lines. This gave me enough slack to put the

plug end back together and plug it into the MAF. This problem was

directly due to the MAF being skewed upwards by 30 degrees.

The

MAF wiring needed to be taken apart and separated a bit from the main harness

and re-routed over some water lines. This gave me enough slack to put the

plug end back together and plug it into the MAF. This problem was

directly due to the MAF being skewed upwards by 30 degrees.

This

is the air inlet tube installed onto the box. It draws cold air from the

radiator area behind the grill.

This

is the air inlet tube installed onto the box. It draws cold air from the

radiator area behind the grill.

This

is the air inlet tube viewed from the front of the CLK. The stock CLK air

scoop is not currently installed.

This

is the air inlet tube viewed from the front of the CLK. The stock CLK air

scoop is not currently installed.

Here you can see the additional air inlet which is routed down into the

bumper area, its a tight fit on the CLK, mainly because of the electric water

pump and additional intercooler tubing that is in the car, but it works.

Here

is the finished product, all cleaned up. You will notice that I secured

the MAF wires using zip ties to reduce strain on the actual MAF connector.

There is some slack in the wiring, and revving of the motor does not move the

motor enough to put a strain on the wire.

Here

is the finished product, all cleaned up. You will notice that I secured

the MAF wires using zip ties to reduce strain on the actual MAF connector.

There is some slack in the wiring, and revving of the motor does not move the

motor enough to put a strain on the wire.

Since

the C36 airbox didn't fit the MAF very well, I purchased a stock CLK320 airbox

and mated the top of the new box to the bottom of the C36 airbox. This

allowed me to fix the MAF fitment issues but still benefit from the higher

flowing bottom section of the C36 airbox.

Since

the C36 airbox didn't fit the MAF very well, I purchased a stock CLK320 airbox

and mated the top of the new box to the bottom of the C36 airbox. This

allowed me to fix the MAF fitment issues but still benefit from the higher

flowing bottom section of the C36 airbox.

Unichip Piggy Back ECU installation

With

the addition of the smaller SC pulley, we have increased boost, so we must be

able to control timing and fuel. The stock ECU is not programmable,

although it can and has been re-flashed, to take into consideration of extra

performance add-ons, you need to be able to dyno tune your car. Not much

is available for Mercedes, but Unichip offers a universal piggy back ecu that

needs to be hard wired between the stock ecu and the car. So its back to

see Alex at www.carbconn.com in Kirkland,

who is the local expert for tuning forced induction vehicles.

With

the addition of the smaller SC pulley, we have increased boost, so we must be

able to control timing and fuel. The stock ECU is not programmable,

although it can and has been re-flashed, to take into consideration of extra

performance add-ons, you need to be able to dyno tune your car. Not much

is available for Mercedes, but Unichip offers a universal piggy back ecu that

needs to be hard wired between the stock ecu and the car. So its back to

see Alex at www.carbconn.com in Kirkland,

who is the local expert for tuning forced induction vehicles.

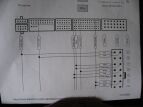

Alex

logged into his dealer account at Unichip and searched their database for

suitable wiring diagrams, he found a schematic for a 2001 E240, which uses the

same M112 motor as my car, just a smaller displacement. We closely

examined my ecu and wire harness and found it to be a exact match to the E240.

Alex

logged into his dealer account at Unichip and searched their database for

suitable wiring diagrams, he found a schematic for a 2001 E240, which uses the

same M112 motor as my car, just a smaller displacement. We closely

examined my ecu and wire harness and found it to be a exact match to the E240.

A

better view of the E240 wiring diagram. The installation requires

identifying certain ecu wires and then splicing the Unichip into these wires.

A

better view of the E240 wiring diagram. The installation requires

identifying certain ecu wires and then splicing the Unichip into these wires.

For

longevity, all connections should be solder/crimped with heat shrink applied to

secure the splices.

For

longevity, all connections should be solder/crimped with heat shrink applied to

secure the splices.

Another

picture detailing the splicing work

Another

picture detailing the splicing work

With

the Unichip installed, it was time to verify that it would accept commands from

the programming terminal, so we proceeded to test it by adjusting fuel/timing.

With

the Unichip installed, it was time to verify that it would accept commands from

the programming terminal, so we proceeded to test it by adjusting fuel/timing.

The

Unichip is plugged into this module, which in turn in plugged into a laptop

computer. We can then adjust fuel trims and timing throughout the rev

band. This is done at standstill, driving and on the dyno doing WOT runs.

We were aiming for a nice 12.5 AF and no pinging at redline.

The

Unichip is plugged into this module, which in turn in plugged into a laptop

computer. We can then adjust fuel trims and timing throughout the rev

band. This is done at standstill, driving and on the dyno doing WOT runs.

We were aiming for a nice 12.5 AF and no pinging at redline.

This

is the picture of the Unichip console. Upon our first round of tuning, we

discovered we were hitting 100% duty cycle on the stock injectors, right around

4800 rpm.

This

is the picture of the Unichip console. Upon our first round of tuning, we

discovered we were hitting 100% duty cycle on the stock injectors, right around

4800 rpm.

Dyno Tuning, injector installation and misc.

Once

you jump into the world of custom tuning and performance enhancement, all sorts

of things pop up. Kleemann uses a rising rate fuel pressure regulator to

assist fuel requirements on their SC kit. With the Unichip, we didn't need

this anymore, so we had to disconnect it.

Once

you jump into the world of custom tuning and performance enhancement, all sorts

of things pop up. Kleemann uses a rising rate fuel pressure regulator to

assist fuel requirements on their SC kit. With the Unichip, we didn't need

this anymore, so we had to disconnect it.

Since

we were hitting 100% duty cycle on the stock injectors, it was time for a

upgrade. The C32 AMG model uses 40lb injectors (stock clk injectors are

19lb). So I acquired a set of the new injectors, which are light blue in

color.

Since

we were hitting 100% duty cycle on the stock injectors, it was time for a

upgrade. The C32 AMG model uses 40lb injectors (stock clk injectors are

19lb). So I acquired a set of the new injectors, which are light blue in

color.

To

determine the flow of these new injectors vs. the stock injectors, Alex ran them

through his injector flow bench. As you can see, the C32 injectors flow

double the amount of fuel as the stock injectors. We tested all six

injectors to confirm flow rates and spray pattern before we installed the

injectors.

To

determine the flow of these new injectors vs. the stock injectors, Alex ran them

through his injector flow bench. As you can see, the C32 injectors flow

double the amount of fuel as the stock injectors. We tested all six

injectors to confirm flow rates and spray pattern before we installed the

injectors.

Although

our tuning is not yet finished, we are seeing around 270 rwhp and 240lbs of

torque. This is a 20 rwhp increase and 30lbs of torque increase over the stock

76mm SC pulley.

Although

our tuning is not yet finished, we are seeing around 270 rwhp and 240lbs of

torque. This is a 20 rwhp increase and 30lbs of torque increase over the stock

76mm SC pulley.

To see the clk32k on the dyno, click the play button

<Back

Information/pictures on this site are the property of Rik Johnson and are not

to be used without written permission.